Our partners in Canada has recently installed a structure in 8 days. As part of developing the last four-lane section of Highway 97 in the Okanagan Valley, AIL was contracted to design and supply a Bolt-A-Plate recreational trail and wildlife underpass.

When ACP was approached by Bardavcol Pty Ltd. and asked to manufacture and supply a customised Multi-Plate™ Arch in record time, they were eager to take on the challenge.

ACP is experienced in finding alternative solutions that offer your projects the same functionality and quality at a better value.

We call it Value Engineering.

See how ACP can save you time and money on your projects without sacrificing quality or functionality.

West Australian mining giant Alcoa has recently relocated its Willowdale bauxite mine site from the 20 year old Orion location to a new location known as Larego. This challenging move included the safe relocation of an 850 metric tonne crusher to the new area, set to be the centre of the mine’s operations for the coming decades.

Multi-Plate offers distinct advantages including: high strength to weight ratio / a wide range of shapes and sizes / easy handling and shipping / economical / can be pre-assembled or assembled on site.

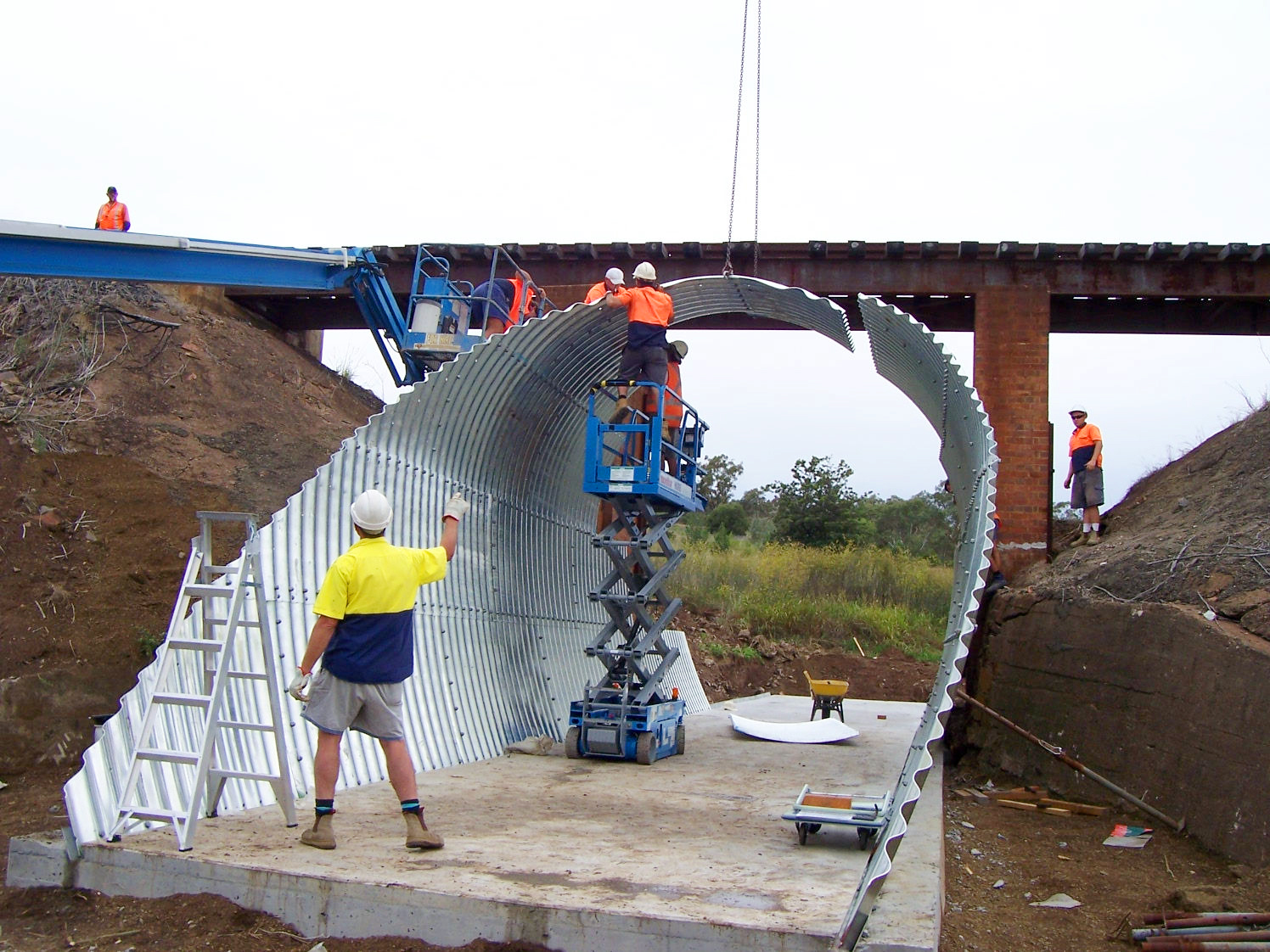

This project improved the efficiency of the main rail line between Sydney and Melbourne. The project involved constructing a 5 km dual track rail bypass of Wodonga, and included a new train station, seven bridges, and this arch.

Multi-Plate offers distinct advantages including: high strength to weight ratio / a wide range of shapes and sizes / easy

handling and shipping / economical / can be pre-assembled or assembled on site.

A project carried out in Ravensworth NSW for a coal company where we manufactured and delivered Multi-Plate Arch Type HA for a reclaim conveyor.

This project focuses on the manufacture and delivery of Multi-Plate Arch Type HA for conveyor egress for a project being carried out at the Westcliff Colliery in Appin NSW.

Australian Construction Products (ACP) worked closely with the stakeholders, Nepean Conveyors and the consultants, Lindsay & Dynan. Project urgency required a prompt response to come up with a solution to the awkward challenge of the steep decline and the conveyor skew alignment.