Description

Revolutionising tunnel liner plate construction methods and application ranges.

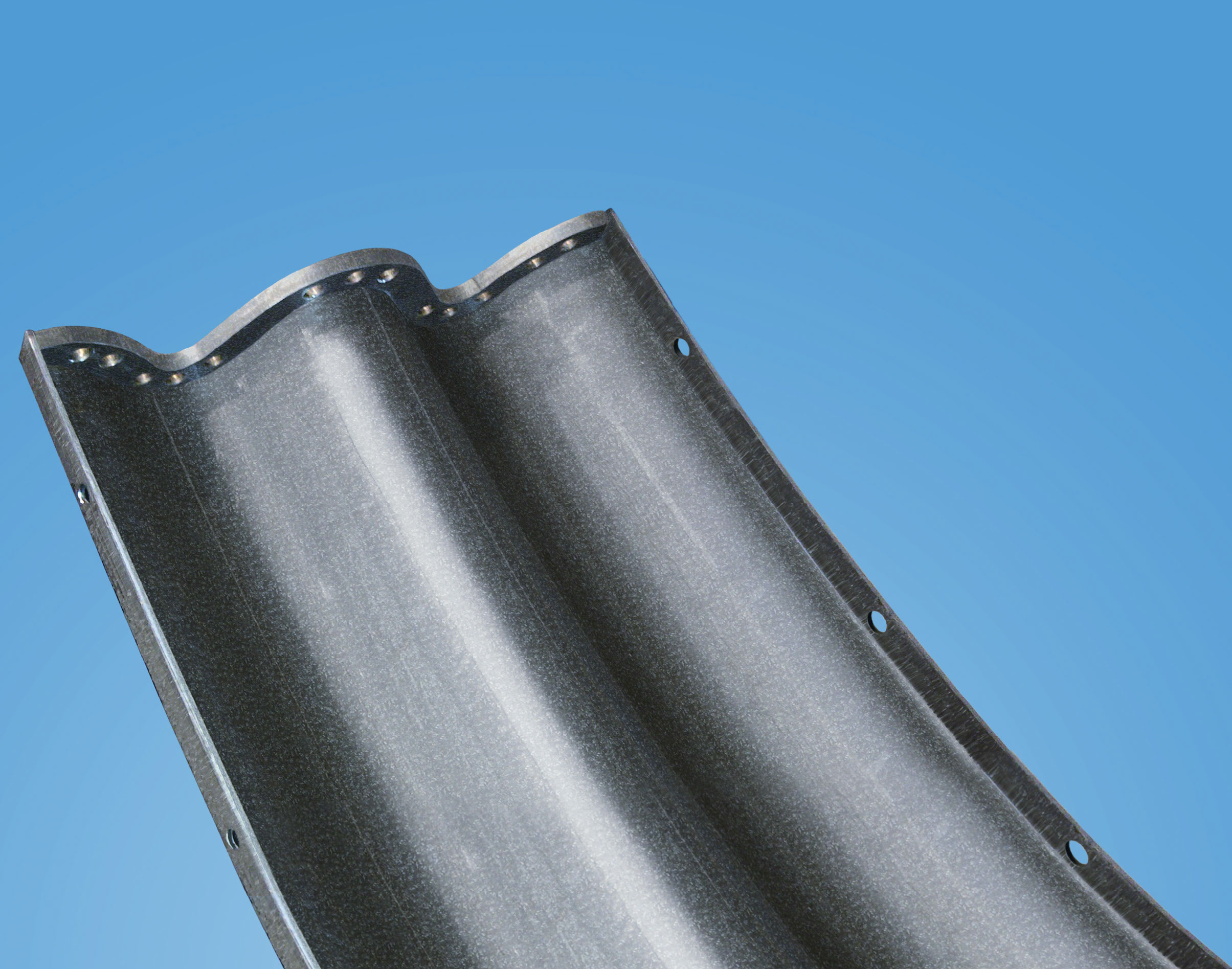

Ten times stiffer, five times stronger than traditional tunnel liner plate

The flanges add significant strength to the steel plates, buried arch bridges, deep coil tunnels and other structures, often reducing the need for reinforcement ribs on applications like large tunnels, overpasses or support structures.

Build corrugated metal structures from one side — faster, safer and more accurately

THE EDGE Four-Flange Structural Liner allows for better fitting/assembly of plates and that means smaller crews and a lower installed cost. The flanges can be built on the outside or the inside of a structure, so assembly work can all be carried out from one side when access is restrictive. Underground tunnels, support structures and shaft liners can be completely built from the inside. Corrugated metal structures over-functioning rail lines, conveyors or streams can be built from the outside.

Custom-curved or leak-resistant corrugated steel structures

Optional custom-flanged plates can be incorporated to facilitate curved structures, and gaskets can be added to the flange seams to provide leak-resistance for a wide array of corrugated metal applications.

Recommended for tunnels, shafts and other mining applications

THE EDGE Four-Flange Structural Liner is recommended for mine shafts, vent raises, escape-ways, portals, canopies, ground support structures, relining of existing structures, road or rail overpasses, heavy haul road crossings, stockpile tunnels, storage structures and protection structures.

Recommended for bridge construction and other transportation applications

Tunnels, vertical shaft liners for CSO or commuter rail projects, road or rail overpasses, grade separations, bridges, relines of existing structures, ground support and control, protection structures, storage structures and water intake structures.

Discover the many benefits of buried arch bridges

Structural plate bridges or buried arch bridges offer many advantages over concrete equivalents and traditional site-built beam bridges, truss bridges or concrete drainage pipes.

Bring enhanced aesthetics to your buried arch bridges

From interior finishes and lighting to exterior end treatments and even urban greenways on top, take a look at the full range of possibilities for buried arch bridges in our Design Ideas Gallery.

Features and Benefits

- 10 times stiffer and 5 times stronger than traditional steel liner plate

- Handles extreme loadings

- Accelerated assembly, easier fitting of plates

- Smaller crews needed, lower installed costs

- Added safety, structures can be built from one side

- Easy to ship and install for remote locations

- Long-lasting and virtually maintenance-free

- Suitable for field-applied coatings

- Grout coupling sizes and placement to suit site conditions

- Custom fittings

- Gaskets allow for leak-resistant structures

- Lower cost tank storage option

- Structures can be dismantled and removed

Specifications

- Spans can exceed 25m (82′)

- Corrugation profile of 381mm (15″) pitch and 140mm (5.5″) depth

- Available in traditional and custom shapes

- Available uncoated or with hot-dip galvanised or Best

- Kote Polymer coatings